Innovation in electric vehicles and energy storage from renewable sources are two key drivers in the rapid growth of a battery industry that is striving to improve performance of battery systems with great urgency.

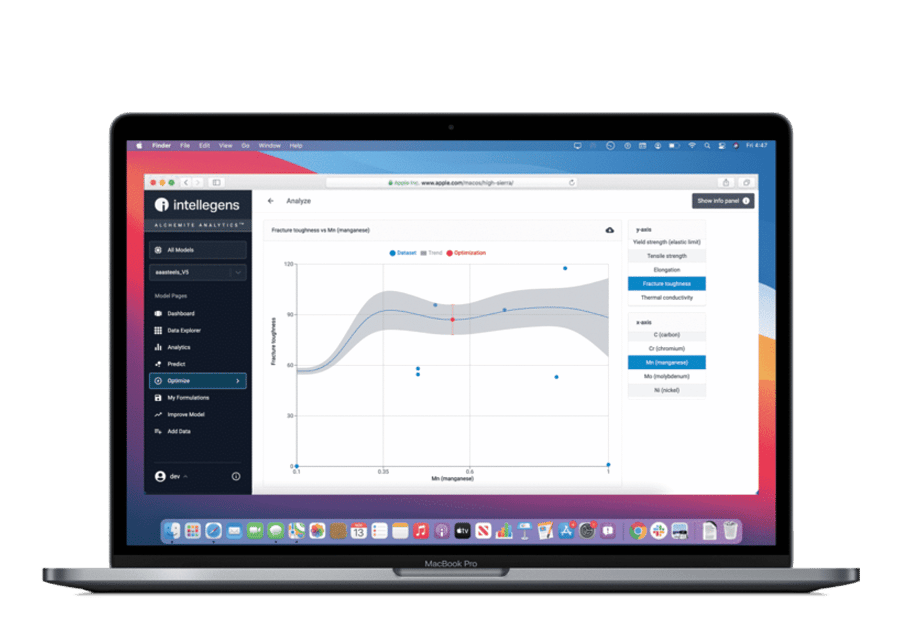

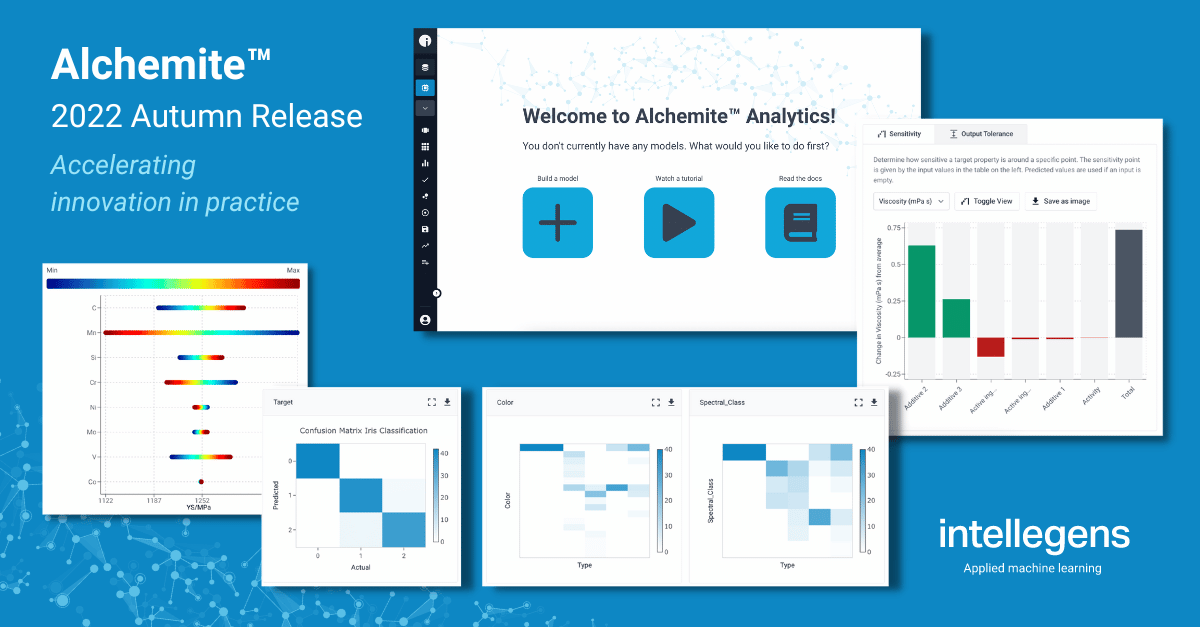

Machine learning can help, extracting value from existing data to accelerate the development of new battery materials and formulations, optimise the design of battery packs, and enable more effective battery management systems. The Alchemite™ deep learning software was designed for such complex prediction and optimisation problems, where data is often sparse and noisy.

Example projects

Optimising production processes and battery chemistry

In a project with industry and academic partners, Alchemite™ machine learning was applied to optimise the formulation and manufacturing of electrodes for lithium-ion batteries. Conventionally, improvements are identified via trial-and-error, with a large matrix of experiments. Use of Alchemite™ to predict electrode performance focuses such experiment and reduces the development time for new battery chemistries. At the end of the project, the proposed electrodes were manufactured and showed excellent lifecycle and capacity, as predicted.

Data-driven machine learning for battery management

A collaboration between the University of Cambridge, A*STAR and Nanyang Technological University in Singapore, assessed methods for predicting electric vehicle battery states and revealed that a data-driven machine learning model offers the most accurate predictions for State of Charge (SOC) and State of Health (SOH). The project provides a case study for machine learning accurately predicting the health and life of a battery, with the potential for manufacturers to embed these methods into their battery devices, improving in-life service for the consumer.

Learn more

Recorded webinar: Machine learning for batteries

Intellegens were joined by battery experts Deregallera for this webinar to discuss how machine learning is applied in three key areas of battery development: (1) Battery materials and formulations; (2) Cell and pack design; (3) Battery management systems. View the recording to see how machine learning helps improve charging capacity and energy density, lower development times and costs, and enable more efficient operation.

Article: Battery R&D – the rise of machine learning

BEST magazine speaks to Intellegens CTO, Dr Gareth Conduit.

Alchemite™ for batteries

Design testing programs to achieve objectives with the fewest experiments or prototypes

- Propose new battery materials or chemistries

- Select and optimise process parameters to improve battery manufacturing

- Trade-off size, weight, power, charge speed, lifetime, etc. in designing battery packs

- Inform control systems for battery management, including state of charge and safety monitoring